BLUEBERRY PACKAGING

Berryguard™

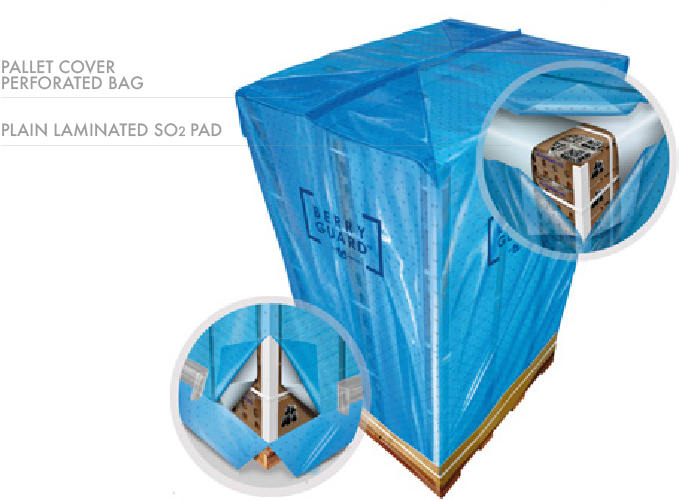

BLUEBERRY PACKAGING TECHNOLOGY / PALLET

Berry Guard™ is an innovative packaging system developed by OSKU and validated by Davis, University of California and important Chilean Blueberry Export Companies.

The system comprises a pallet-cover bag controlling the relative humidity and 5 bands of pads releasing Sulfur Dioxide (SO₂) which together effectively control the development of Botrytis Cinerea on blueberries.

The product allows extended times of transit and/or storage. Berry Guard™ pads are devices that are composed of laminated covered polymers which stably control the SO₂ emission by applying very low dosis of gas to the fruit with the purpose of stopping the action of Botrytis Cinerea.

Berryguard™

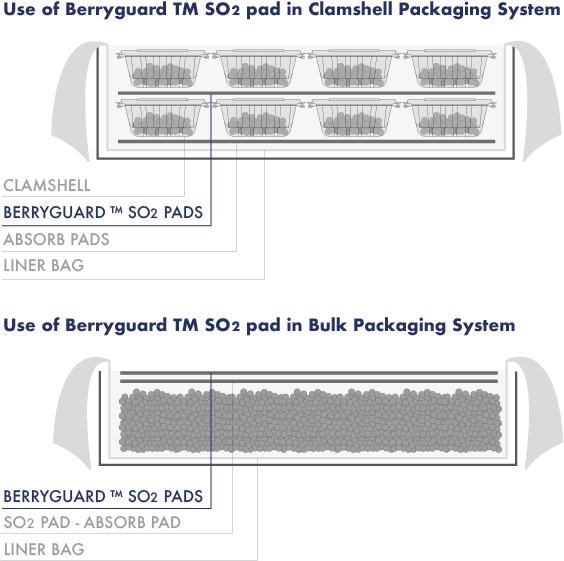

BLUEBERRY PACKAGING TECHNOLOGY / BOX TO BOX SYSTEM

Berryguard pads are devices compounding coated laminated polymers which stably control SO₂ emission applying a very low dosage of this gas to the fruit with the purpose of stopping the action of Botrytis Cinerea fungus. It can be adapted to up to 4 types of packaging sizes and perforations are precisely designed to facilitate the adequate ventilation and gas emission inside of the box .

The density of the plastic barrier and the specific particle size of the active ingredient Na₂S₂O₅ allows an homogeneous and stable release of sodium metabisulfite during transit and/or storage of fruit .

The box to box Berry Guard ™ system is a different and innovative application of the SO₂ generating device in blueberry transits and/or storage with excellent results in both clamshell and bulk shipments.

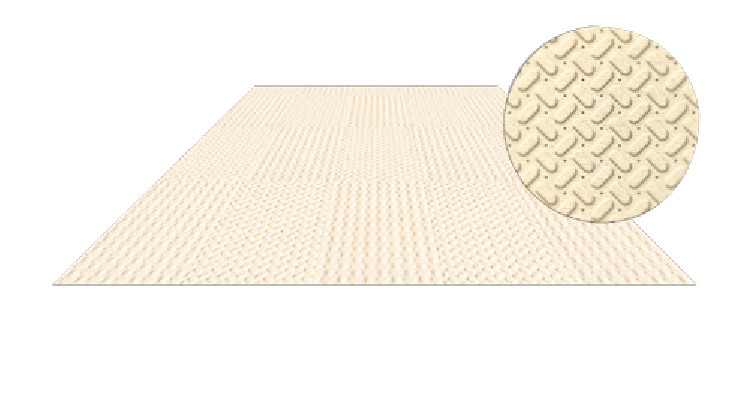

Absorb Pads

Absorb pad is a virgin paper sheet, elaborated with a 100% of natural fibers from the Pine`s pulp. It is specially designed for direct contact with food products for human consumption.

There are no chemicals, additives or colorants involved in its manufacturing process, complying all FDA regulation and standards for this type of product.

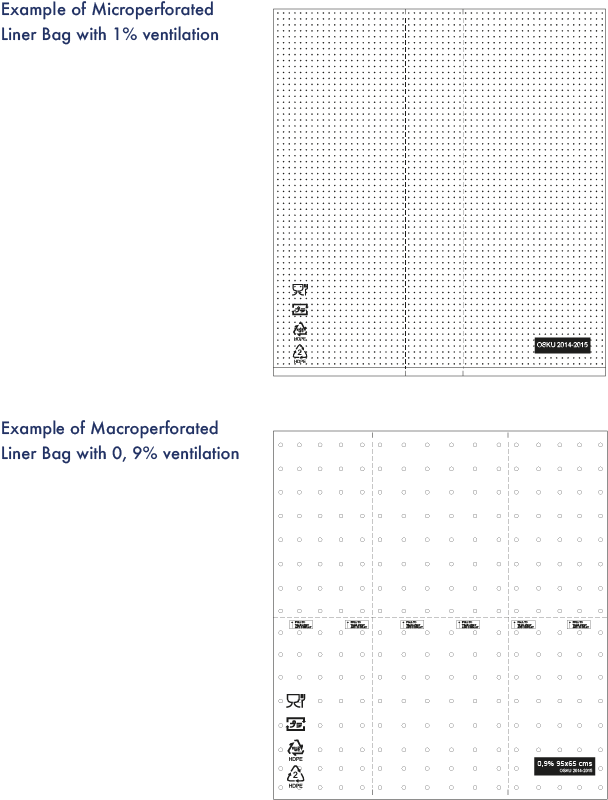

Liner Bags

Liner bags are made with High density polyethylene designed to over wrap the blueberries inside the carton, becoming an important device of the packaging system.

These liner bags can be perforated in order to comply USDA regulation and others, regarding ventilation.

The materials used in the manufacture of this product are approved by FDA/ USA and are 100% virgin.

FEATURES:

• Macro or microperforated.

• Diverse % of ventilation (acccording to client`s needs).

• Diverse sizes (according to client`s needs).

• Pre-cut or not.

• Allows printing.

BEST FOR:

Fresh Blueberry Producers / Exporters